- detail

- parameters

hollow drilling mining rock grouting anchor bolt

1, hollow drilling mining rock grouting anchor bolt consists of hollow core with continuous hot-rolled outside thread

2, hollow drilling mining rock grouting anchor bolt can application as injection anchor without casing, especially for non-stable boreholes

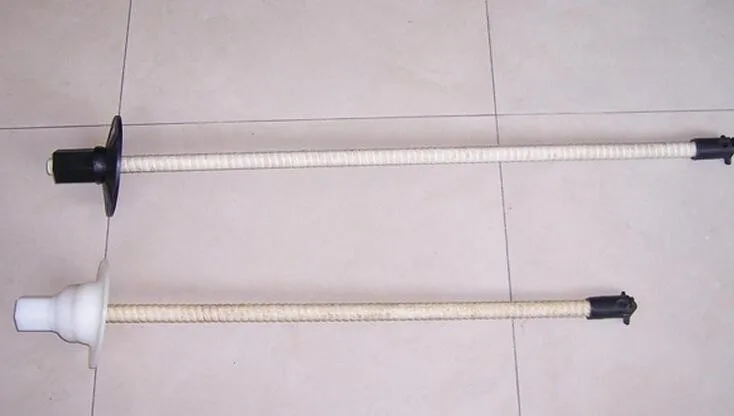

tunnel plastic sleeve anchor rod

the advantage of tunnel plastic sleeve anchor rods driven by a metal rod plastic cone, plastic expansion sleeve so close to the rock wall of the hole, to achieve anchoring the anchor resin bonded to abandon the traditional mode without anchoring agent. save money, reduce labor intensity, reducing transport volume, save energy, reduce support costs,it can be widely used in coal mine tunnel, culverts, tunnels and other security support fields.

hollow drilling mining rock grouting anchor bolt

introduction

* high strength mining self drilling hollow rock anchor drill bolt is widely used in road / rail construction and maintenance

* rock bolt can be used for tunneling & mining

* rural environments

* private residences

* special foundations

* avalanche protection structures

main advantages

1, easy and similar operation principle for different rock mass and soil conditions.

2, drilling, anchoring and grouting can be performed in one single operation.

3, no pre-drilling of a borehole by using a casing tube and extension rods with subsequent anchor installationnecessary.

4, minor space requirement for the accomplishment of anchoring.

5, optimized machinery and manpower requirements.

6, basic dimensioning of the required anchoring forces by choosing the appropriate anchor type.

7, optimum bonding of the profiled anchor rod and the grout.

8, adjustment of the drill bit design and diameter to different rock mass and ground conditions.

9, simple anti-corrosion method available.

10, appropriate for temporary or permanent applications.

tunnel plastic sleeve anchor rod introduction

test anchoring force ≥ 50kn (meet mt146.1-2002 specification)

model rod diameter (mm) analog aperture (mm) integrated anchoring force (kn)

32 type φ14 32 2 ≥ 400

φ16 32 2 ≥500

42 type φ14 42 2≥400

φ16 42 2 ≥500

φ18 42 2 ≥700

2.retardant antistatic meet mt133-1995 specification

3. metal rod, pallet recycling reuse.

mine locomotives

grilled slag machine

mine wagon

scraper winch

hydraulic jumbolter

rescue capsule

advantages.1

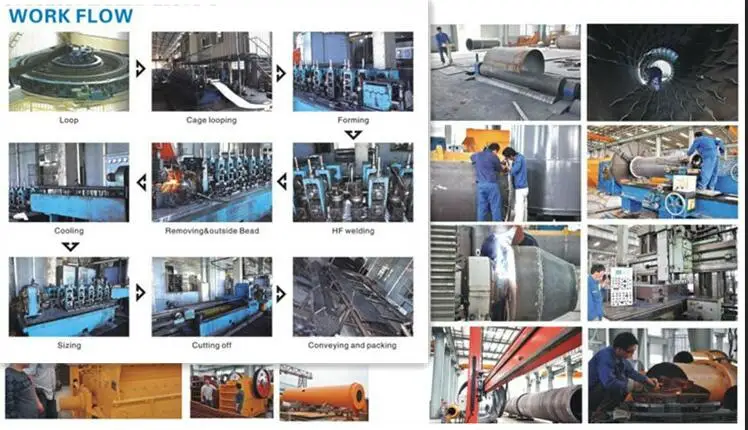

our companies to actively participate in railway and mining construction for more than 30 years. for the domestic railway, coal mines, subway,ports, such as steel rail transport to open in the field of equipment shortages, roads, offers a wide range of materials.

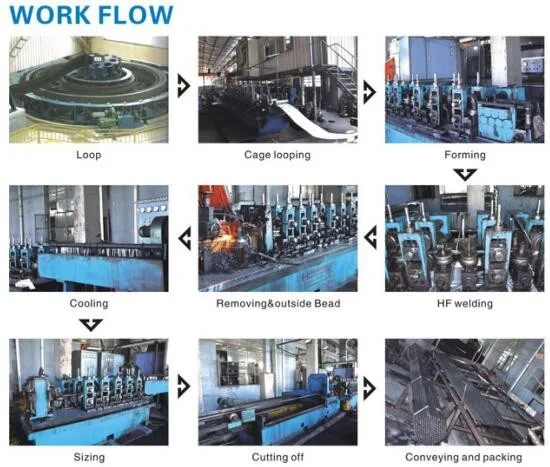

advantages.2

in order to strictly control the quality of each product and ensure that all our railway and mining equipment meet international standards and our customers' expectations, our advanced manufacturing equipment includes the following: vertical milling machining center ,numerical control lathe, numerical control cutting,and all kinds of equipment more than ten hundreds .

q1: are you trading company or manufacturer ?

a: we are a manufacturere with 7 branch factories and 6 overseas offices.

q2: how long is your delivery time?

a: generally, within 15-25 days after deposit received.

q3: can we visit you factory?

a: warmly welcome! once we have your schedule, we will arrange the professional engineers and salesperson to follow up your case.

q4: do you provide samples ? is it free or extra ?

a: available upon request.

q5: what is your terms of payment ?

a: tt b. western union c. lc d.upon request

q6. is it ok to print my logo on product?

a: yes. please inform us formally before our production and confirm the design firstly.

q7. why choose our company?

a: 1.we have 30 years working experience in railway and mining construction.

2. we have 31 professional engineers and 6 overseas office for better after-sales service .