- detail

- parameters

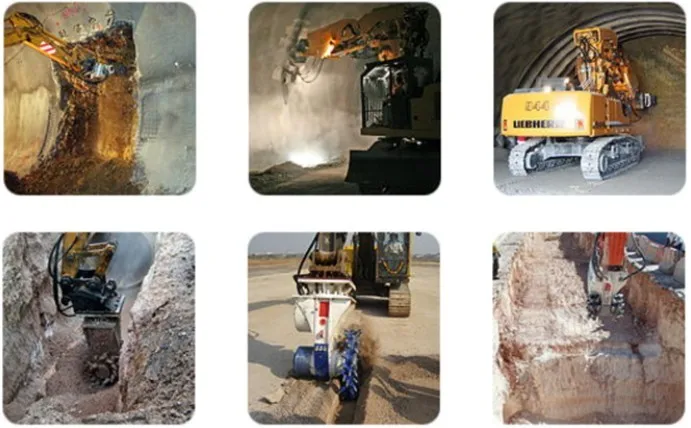

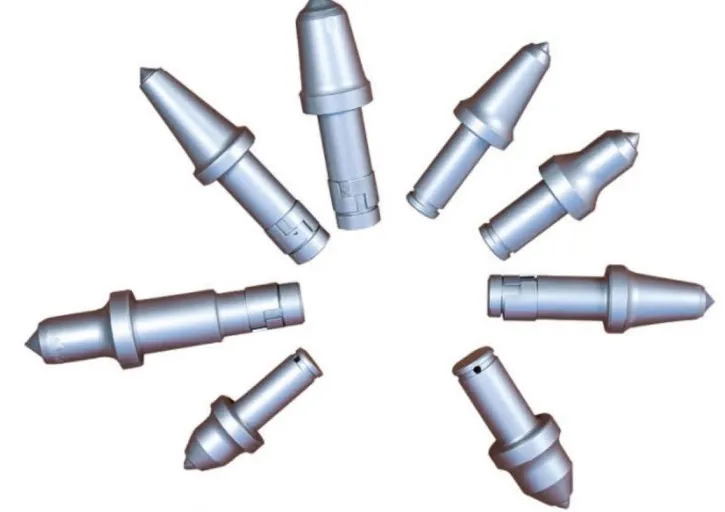

carbide cutting teeth introduction

cutting teeth material.

the tooth body is made of high quality cold extrusion 42crmo, high density not decarburization. numerical control lathe processing ensures consistent size. with special heat treatment process of 40-45 degrees, its surface is almost no oxidation, tooth head using isothermal quenching process, its hardness doesn't reduce. production of cemented carbide by formal domestic companiesyg11c, stable quality can accord customer needs to add welding wear-resisting layer, hardness reaches more than 65 degrees.

advantages

1. 100% raw material to produce tungsten carbide products.

2. hip sintered, high hardness, high wear resistance

3. various sizes and full types available

4. reasonable price,fast delivery time

5. oem customized(small order accepted,professional technical support)

6.iso 9001 certification

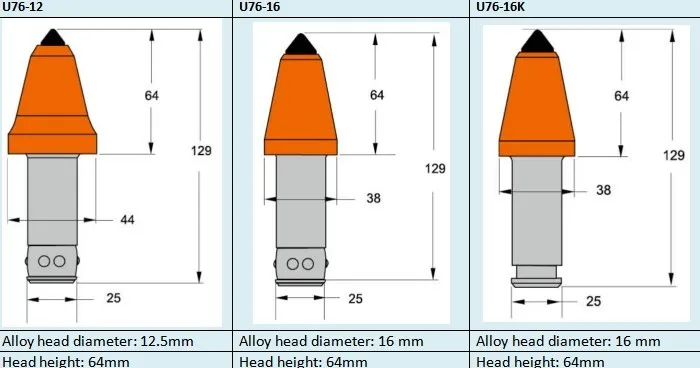

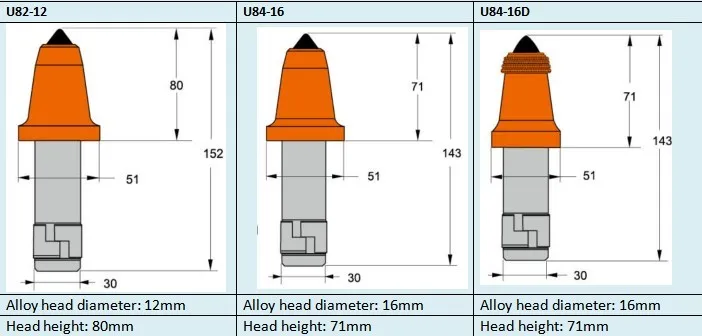

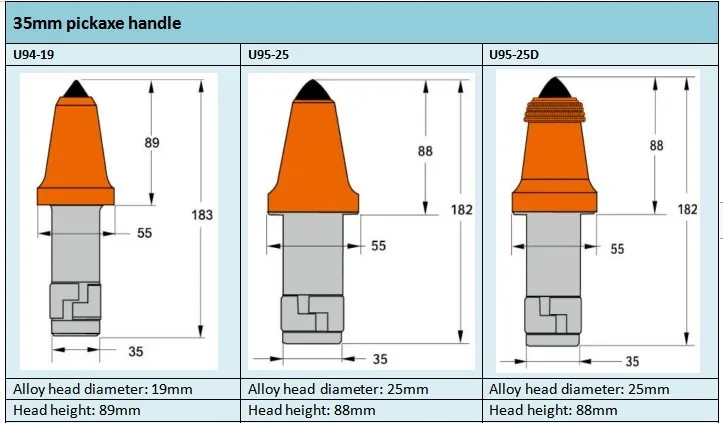

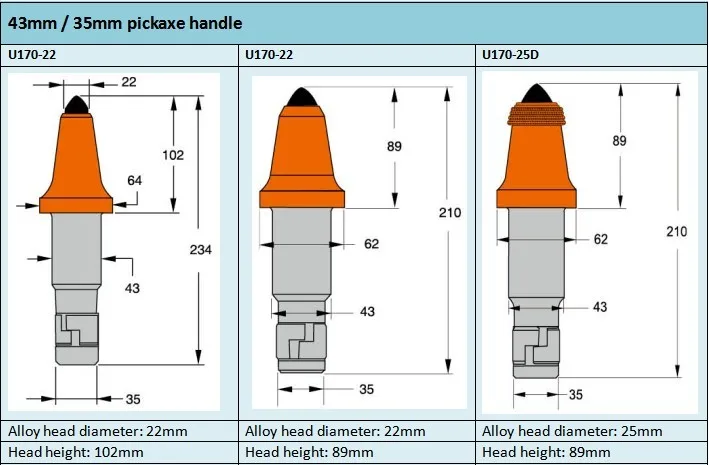

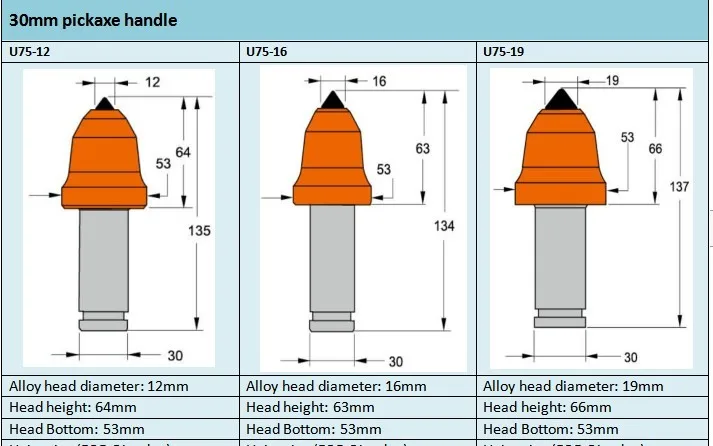

cutting teeth model

1.mining carbide:tungsten carbide inserts,mining bits,cemented carbide alloy tooth,carbide button inserts-parabolic/conical/chisel,inserts for round shank picks.

2.carbide insert for oil field:drill bit,carbide tips,saw blades

3.wear part tungsten carbide: 40 50 60 76 89 102 115 127 drill

4.>mining drill bits:cross bits,conical tools,radial tools,two wing drill bits,three wing drill bits,special tools tips.

cutting teeth more information

models

according to different working conditions, we prepare a complete set in the diameter of alloy head, geometry shape of the knife-blade and the size of the knife-handle. under different geological conditions, we kindly recommend you to choose the appropriate conical tools.

mine locomotives

grilled slag machine

mine wagon

scraper winch

hydraulic jumbolter

rescue capsule

advantages.1

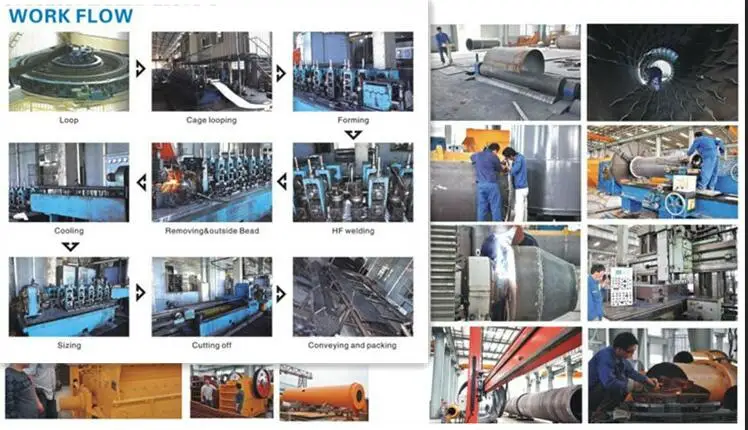

our companies to actively participate in railway and mining construction for more than 30 years. for the domestic railway, coal mines, subway,ports, such as steel rail transport to open in the field of equipment shortages, roads, offers a wide range of materials.

advantages.2

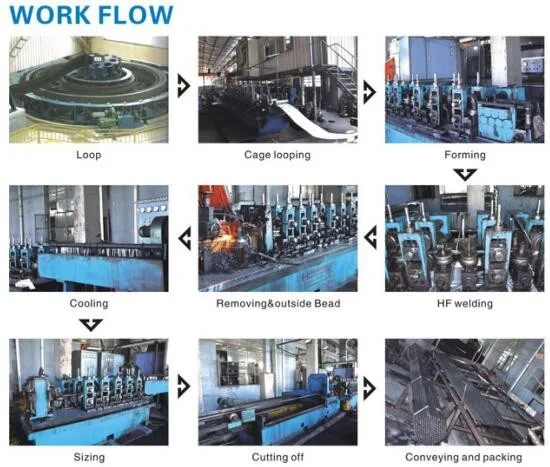

in order to strictly control the quality of each product and ensure that all our railway and mining equipment meet international standards and our customers' expectations, our advanced manufacturing equipment includes the following: vertical milling machining center ,numerical control lathe, numerical control cutting,and all kinds of equipment more than ten hundreds .

q1: are you trading company or manufacturer ?

a: we are a manufacturere with 7 branch factories and 6 overseas offices.

q2: how long is your delivery time?

a: generally, within 15-25 days after deposit received.

q3: can we visit you factory?

a: warmly welcome! once we have your schedule, we will arrange the professional engineers and salesperson to follow up your case.

q4: do you provide samples ? is it free or extra ?

a: available upon request.

q5: what is your terms of payment ?

a: tt b. western union c. lc d.upon request

q6. is it ok to print my logo on product?

a: yes. please inform us formally before our production and confirm the design firstly.

q7. why choose our company?

a: 1.we have 30 years working experience in railway and mining construction.

2. we have 31 professional engineers and 6 overseas office for better after-sales service .